In 2025, a major shift in fire safety regulations will take place – the complete ban on PFOA-based firefighting foams.

Environmental and safety standards are constantly changing and adapting to new dangers and discoveries. But, while compliance is always key, we cannot understate the urgent action businesses must take to address their usage of legacy fire suppression systems.

What’s in this guide?

Heavily relying on suppression systems to prevent large-scale incidents cannot be interrupted.

But, as the tighter restrictions on PFOA and PFAS have raised concerns for the future of Aqueous Film Forming Foam (AFFF) fire suppression systems in the UK, questions about how to maintain recycling centre fire safety are on everybody’s lips.

In this guide, we’ll explain what the upcoming PFOA ban means for businesses, particularly in the waste management and recycling sector. Keep reading to know how it will affect existing fire suppression systems, and what alternatives are available to stay compliant…

What Is the 2025 PFOA Ban?

The July 2025 PFOA ban has implications for PFAS and AFFF systems as a whole. First of all, let’s make sure we know what each of those terms means:

- PFOA (perfluorooctanoic acid) is a manmade chemical used in fire suppression systems

- PFAS (perfluoroalkyl and polyfluoroalkyl substances) are a large group of synthetic chemicals that includes PFOA

- AFFF (aqueous film forming foam) is a low-expansion fire suppressive foam that may contain PFAS such as PFOA

PFOA has been classified as a Persistent Organic Pollutant (POP) because of its non-biodegradable nature, its toxicity, and its tendency for bioaccumulation (the gradual accumulation of a toxin in an organism or food chain).

The impact of this ban will be felt nationwide due to the immense pressure key industry bodies and regulatory agencies have put on businesses to govern PFAS usage over the years.

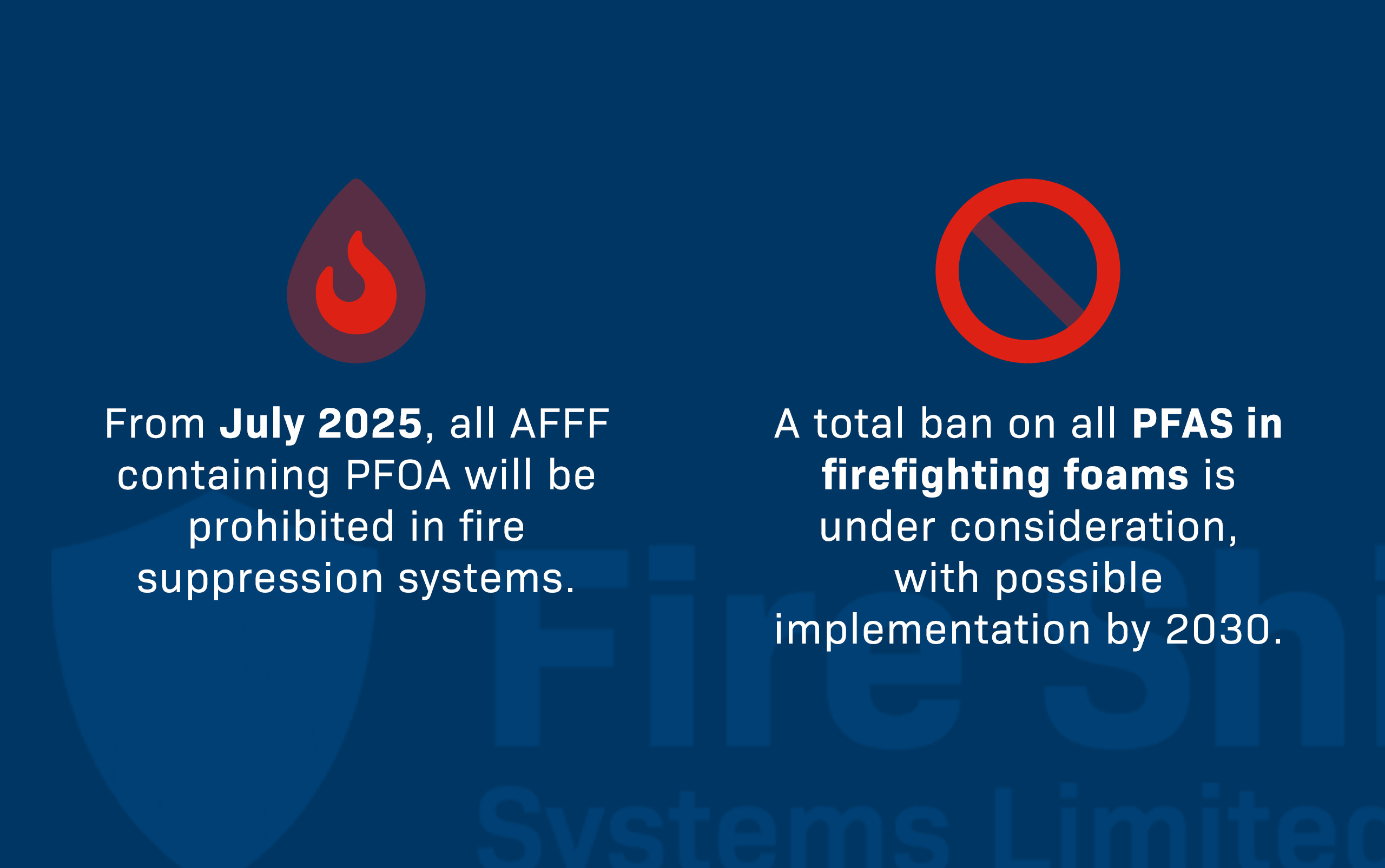

The escalating bans and future implications will be rampant as the 2025 PFOA ban is part of a broader crackdown on PFAS chemicals, following the initial ban of PFOS (Perfluorooctane Sulfonate) in 2009.

In fact, businesses can expect to see a total PFAS ban by 2030 with considerations already underway – but why are regulators waging war on the go-to fire foams?

The Environmental Impact of PFAS Chemicals

PFAS chemicals, often referred to as ‘forever chemicals’, persist in the environment, contaminate water supplies, and pose severe health risks.

The growing regulatory restrictions reflect a global push to eliminate these harmful substances, urging businesses to transition to safer alternatives as soon as possible. This led to the use of PFOA being phased out in 2019, with a grace period to allow existing stocks to be depleted.

In July 2025, the grace period expires and a complete ban on the use of PFOA in fire suppression systems is due to come into effect.

Why is PFOA Being Banned in Fire Suppression?

The PFOA ban in fire suppression is the culmination of decades of work to act on the safety concerns posed by PFAS.

In 2009, under the Stockholm Convention, PFOS (perfluorooctane sulfonate) was banned, but PFOA (perfluorooctanoic acid) was not. It was another decade before an agreement was reached to phase out PFOA, with the full ban finally coming into effect in July 2025.

Governments are now moving towards a total ban on PFAS-based firefighting foams, which could come into effect by 2030.

The moves are an effort to prevent these ‘forever chemicals’ from being released into the environment, which is highly likely following the discharge of an industrial fire suppression system, and a move towards more eco-friendly PFAS-free fire suppression solutions.

Who Will Be Affected by the 2025 Ban?

Following the firefighting foam ban, UK waste management and recycling centres, along with other industrial premises, will face challenges to safely decommission, dispose of, and find AFFF replacement options for legacy systems.

However difficult it may be, acting before the ban comes into effect is crucial. After July 4th 2025, the regulations on disposing of PFOA foams will become much stricter.

Any businesses within the waste and recycling industry should already be looking for an AFFF replacement. It’s not just the waste business – other branches of the industry must keep their eye on the ball too, including:

- Waste and recycling centres, especially those that handle paper, plastics, hazardous waste and other combustible materials

- Waste-to-energy incinerators, which rely heavily on fire suppression systems like AFFF to tackle high-intensity fuel fires

- Landfill sites and industrial storage yards, where rapid-response foam systems are deployed to tackle deep-seated fires in waste materials

With more bans and tighter regulations on the horizon in the coming five years, now is the time to look to fluorine-free foam fire suppression systems to be prepared for the potential phasing out of PFAS.

How Will Waste and Recycling Centres be Impacted?

Ensuring continued recycling centre fire safety in the presence of combustible materials is a necessary part of operations. But, the legal and compliance concerns are just as important for the business’ survival.

For companies to survive the future of waste management fire suppression, they must remain compliant or face hefty fines, compliance penalties, and other liability risks.

This impact will only grow further in the next five years, when it is expected that authorities will expand the ban to include all PFAS chemicals, and not just PFOA.

When making the transition, it’s important to choose the correct alternative fire suppression for incinerators, where fire risks are high and poorly handled incidents can be catastrophic. Failing to do so could lead to costly property damage and/or difficulty when trying to arrange insurance renewals

What Are the Alternatives to AFFF?

The good news is that there are already some excellent AFFF alternatives on the market. Fire Shield Systems have been using fire suppression foams free from harmful ‘forever chemicals’ for several years already.

Our clients are now seeing the benefit of this, with compliant fire safety systems already in place, which in turn frees up our experts to advise those businesses who still need to switch before July.

If you are in that position, we can help you to find the best fire suppression solution for your premises. Let’s look at some of the main options below.

What Are the Best PFAS-free Firefighting Foams for the Waste Sector?

Despite their benefits, fluorine-free foams (F3) are widely assumed to be less effective than traditional AFFF.

In reality, modern PFAS-free alternatives offer the same level of service as their counterparts, all while being environmentally friendly.

If you want a PFAS-free fire suppression system, we can help. Three of the current leading solutions are:

- Fluorine-Free Foam (F3)

- Performance: High-efficiency suppression, particularly effective in solid waste fires and hydrocarbon spills.

- Cost: Generally more affordable than organic foams but may require system adjustments.

- Environmental Impact: Fully PFAS-free but may still leave some residue requiring cleanup.

These foams are best for facilities handling mixed waste, including plastics, wood, and flammable solids, where rapid knockdown is needed.

- Performance: Excellent for solid waste fires, incinerators, and recycling plants.

- Cost: Higher upfront cost but offsets through minimal environmental cleanup.

- Environmental Impact: Fully biodegradable, making it the most eco-friendly option.

These foams are best for operators prioritising sustainability, such as recycling plants and waste-to-energy facilities, where reducing environmental impact is crucial.

- Performance: Best for high-temperature fires and containing spread in combustible waste.

- Cost: Lower operating costs due to minimal water use.

- Environmental Impact: Uses plain water, eliminating chemical residues entirely.

These suppression mists are best for facilities with high fire risk but minimal liquid fuels, such as landfill sites and composting facilities, where controlling temperature and spread is key.

Beyond Waste & Recycling

Waste and recycling centres will be significantly impacted, and other industries are also under pressure to expertly navigate the regulatory demands.

- Industrial storage: Facilities handling hazardous materials will need compliant fire suppression alternatives.

- Aviation: Airports and aircraft maintenance hubs must transition away from legacy foams.

- Chemical plants: Fire safety systems in high-risk chemical production facilities will require updates.

- Fuel storage sites: Bulk fuel terminals must adopt new fire suppression methods to meet safety and environmental standards.

How to Transition to a PFAS-Free Fire Suppression System

Transitioning to PFAS-free waste management fire suppression systems should be a priority ahead of the July 2025 UK firefighting foam ban. Taking action now will help businesses stay compliant and avoid costly last-minute changes.

Unfortunately, the upfront cost of switching fire suppression systems can be a heavy financial burden.

Careful planning can minimise these costs by implementing phased rollouts and scheduled installations to avoid long-term temporary shutdowns

But, we highly recommend planning for the future instead…

By 2030, even stricter regulations could be introduced, potentially banning all PFAS-based systems. Instead, opting for a fully PFAS-free solution now can save businesses from future expenses and operational disruptions.

Fire Shield Systems has been the UK’s leading advocate for PFAS-free alternatives long before the complete ban was announced.

We’re the experts in decommissioning legacy AFFF systems, guaranteeing safe disposal of PFAS-based foams to prevent environmental contamination while keeping costs and disruptions to a minimum.

Planning ahead ensures compliance while keeping costs and disruptions under control. Work with our experienced team to plan a smooth transition with minimal impact on daily operations.

What Steps Should Waste Management Sites Take To Upgrade Their Systems?

Businesses will need to assess their compliance in detail to ensure the crucial accuracy demanded by regulatory bodies.

Our quick five point guide maps out each step:

Step 1: Audit

Check your existing fire suppression systems to identify whether PFOA-based foams are present.

Step 2: Alternatives

Consider the compliant alternatives for your sector e.g. high-performance ‘F3’ fluorine-free foam fire suppression for the waste sector.

Step 3: Decommission

Work with a certified disposal company to decommission old systems, remove PFAS foams and notify the relevant authorities.

Step 4: Upgrade

Install new PFAS-free systems that comply with the current fire safety regulations and plan for likely future bans on PFAS by 2030.

Step 5: Training

Never neglect the human factor. Make sure staff are fully trained on how to use the new firefighting system, in case of an incident.

Fire Shield System Advice for a Smooth Transition

Replacing PFOA-based foams with other PFAS alternatives is a temporary fix—a total PFAS ban could come by 2030. To avoid repeated costs and regulatory risks, invest in a PFAS-free solution now.

Fluorine-free foams (F3) and water mist suppression are effective, proven alternatives that meet both current and future standards, ensuring long-term compliance and cost savings.

Disposing of PFAS-based foams is expensive, so plan ahead, budget accordingly and work with licensed waste management providers to ensure proper handling and compliance with environmental regulations.

Once complete, businesses should immediately notify key stakeholders of system changes:

- Regulators to meet legal requirements.

- Insurance providers to update policies if needed.

- Emergency responders to ensure compatibility with new suppression methods.

Skipping these steps could lead to gaps in fire protection – common pitfalls for non-compliance fines and penalties.

Time for Action on PFAS Systems

The deadline for the UK firefighting foam ban is July 4, 2025. After this date, using PFOA-based fire suppression systems will be illegal, with potential penalties for non-compliance.

Don’t wait until the last minute.

Fire suppression suppliers will be in high demand as the deadline approaches and upgrading early will keep businesses compliant and safe, while ensuring minimal disruption to operations.

At Fire Shield Systems, we specialise in PFAS-free and fluorine-free fire suppression solutions tailored to incinerators, recycling centers, and waste management facilities. With multiple systems available, we can recommend the best fit for your specific fire risks.

Book Your Free Site Assessment Today

Ensure compliance and uninterrupted protection. Contact Fire Shield Systems now to schedule a FREE on-site review and secure your PFAS-free upgrade before the deadline.

To find out more about any of the issues raised on this page, contact Fire Shield Systems now at info@fireshieldsystemsltd.co.uk or call us on +44 (0)800 975 5767.

Contact us

Do you own or operate a business that needs fire protection?

Call us today on 0800 975 5767, or fill in our contact form, to speak with a member of our team.